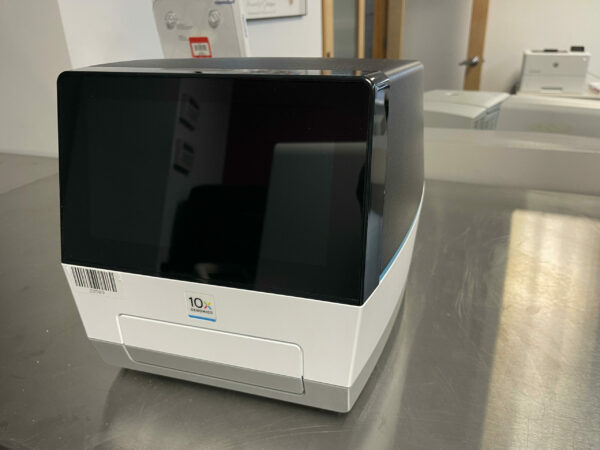

High Quality Used Lab Equipment

At Cambridge Scientific Products, we offer an extensive range of equipment for your laboratory. Interact with our search tool below to explore our current products, or filter by a product category to see our most up to date product offerings in each of these categories. If you don’t happen to see what you want, please contact us. Our equipment inventory is constantly changing and we may be able to locate what you’re looking for if we don’t already have it.

For more information, call 1-877-USED-LAB